“Unmanned” photovoltaic cloud inspection

UAVLUTIONS uses the “non-contact” characteristics of drones to assist operation and maintenance personnel in remote operations and create an unmanned The 3.0 era of “unmanned” aircraft.

At present, in order to effectively develop green, energy-saving and environmentally friendly industries, “double carbon” has become an effective path for my country’s sustainable development, and all walks of life in the country are actively transforming the industrial structure accordingly. As one of the effective “go-getters” in energy structure adjustment, photovoltaics have become an important part of ensuring people’s livelihood. They are a contributor to the implementation of the “double carbon” goal and provide a new supply direction for energy development. With the development and rapid spread of photovoltaic power plants, the refined operation and maintenance of photovoltaic power plants has also been put on the agenda.

Drone inspection 1.0 era: manual inspection

Manual photovoltaic inspection

Drone inspection 2.0 era: pilot + drone inspection

After drones enter photovoltaic inspections, the intensity of manual inspections in the 1.0 era has been alleviated to a certain extent. Pilots can operate drones to achieve high-altitude operations, eliminating the need for workers to travel through mountains and rivers for inspections. However, the pilot + drone mode limits the flight radius of the drone to a certain extent, and the pilot can only extend the distance by changing the scene. At the same time, pilots need to have professional skills and get used to the inspection site. Due to the different levels of pilots, the inspection results obtained are also unsatisfactory. It is difficult for staff to organize data and the maintenance efficiency is low.

Hand-flying drone inspection So what has the drone that has evolved into the 3.0 era brought to photovoltaic inspection?

Drone Inspection 3.0 Era: “Unmanned” Inspection in the Cloud

The UAVLUTIONS PV AI software brought by UAVLUTIONS Intelligence brings drones into a truly “unmanned” new era, bringing full life cycle closed-loop management to photovoltaic power plants.

In view of the particularity of photovoltaic power stations, UAVLUTIONS PV AI has the function of automatic modeling and supports the construction of two-dimensional maps and three-dimensional models of photovoltaic power stations. Users can plan tasks based on the three-dimensional model of the photovoltaic power station.

Station modeling and ID string segmentation

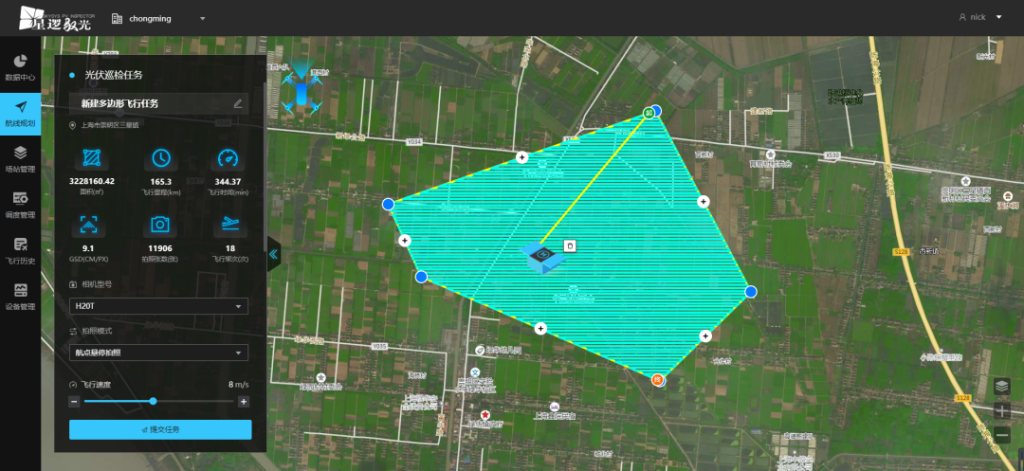

As an independent software, PV AI is decoupled from the drone hangar. The drone can carry the software for daily inspections , and the staff can perform multi-route tasks through various forms of Web/Pad visual scheduling and management terminals. planning to realize one-click takeoff and remote dispatching of drones. The drones can realize functions such as automatic flight, autonomous obstacle avoidance, power-off resume flight, 5G networking, etc. They can know the status of the photovoltaic power station without on-site operations, and the efficiency is compared to Manpower increased 10 times.

Route mission planning

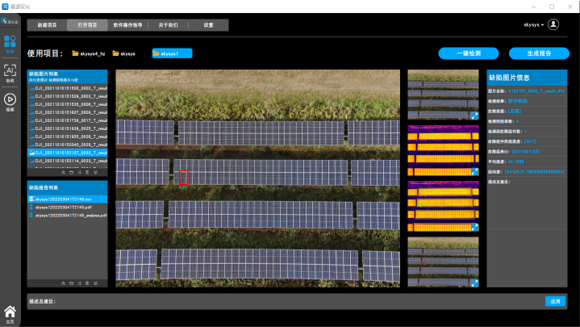

During the flight, the drone monitors the photovoltaic field station in real time through the visible light + thermal imaging camera, and takes vertical shots of the photovoltaic panels to avoid overexposure affecting the detection results. Based on this, Xingluo Yuguang uses AI to intelligently identify defects in photovoltaic panels. Whether they are spots, striped hot spots, empty loads, defects, shadows, or diode failures, PV AI can easily detect them.

Dual-light detection + AI recognition

Since the images detected by the two cameras are different, PV AI double-fuses the defect information and location information detected in the two images, performs fault query, and proposes corresponding solutions for different abnormal defect types. Process suggestions and locate, instantly send location information to the command center, and import defect reports to the mobile terminal to help operation and maintenance personnel patrol and check the relative position of fault hot spots, and quickly and accurately find components.

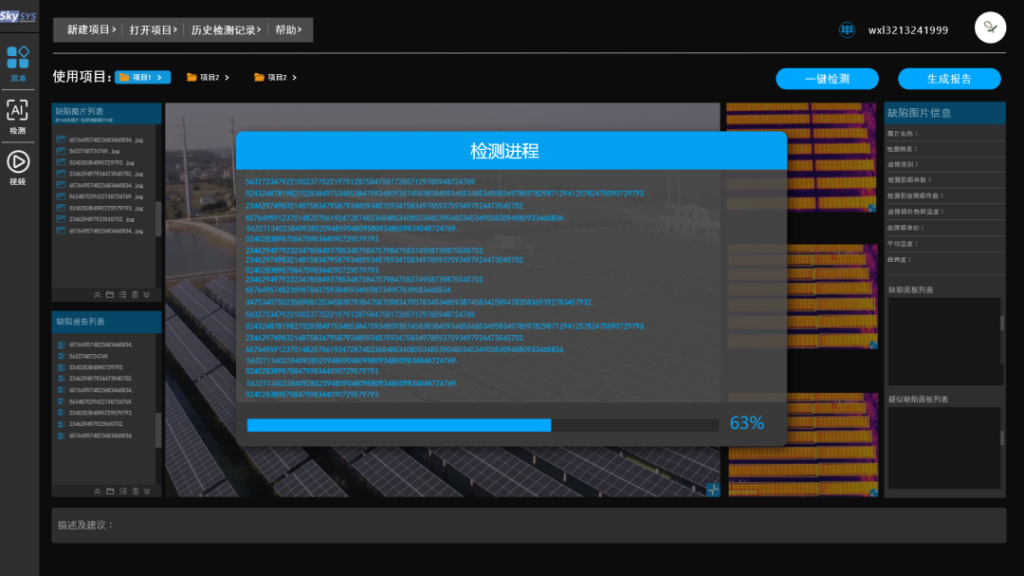

At the end of the detection process , PV AI supports outputting detection reports in multiple formats for users to view. By classifying and counting defects and conducting big data management and analysis from multiple dimensions, we can provide suggestions on common problems of photovoltaic panel defects and lay a “precautionary shot” for daily operation and maintenance. At the same time, PV AI has also realized open source, considering the actual configuration of users, and providing users with high-quality, low-cost, flexible and adaptable photovoltaic inspection services. As a drone photovoltaic inspection software, PV AI cuts into the practice of new energy development from the perspective of drone automation technology and makes contributions to promote the low-carbon transformation of energy and maintain the balanced development of economic, social and ecological benefits. contribute.

Highlights of implemented projects

The UAVLUTINS project in Shanghai,

Jiangxi ,

Inner Mongolia and Zhejiang

has now been implemented across the country. It uses independently developed technology to assist users in achieving normalized operation and maintenance of drones, applying the advantages of aerial operations and AI technology to the actual needs of the scene, creating a diversified , flexible and efficient cloud system model.